“Automate your logistics operations with Artificial Intelligence in supply chain services.”

Are you in a logistics business and worried about inventory management? Don’t worry! AI in supply chain is the best solution for all your problems, offering analysis, automation, and prediction of regular demand.

The technology is accepted worldwide because of its capability to enhance business operations and improve service delivery. Using AI for supply chain management is beneficial for businesses, as the market will grow rapidly in the future.

A general economic forum published a report in 2025, which showed the growth of the supply chain market at an 11.4% CAGR between 2025 and 2030. By looking at the potential of this industry, businesses have now increased the value of their investments in supply chain planning solutions. More revenue is expected by the end of this tenure.

This blog tells about the top Generative AI use cases in the supply chain sector with its benefits, roles, and challenges in the future. Additionally, we will also look at the integration process in the content. So, let’s move further to understand detailed information.

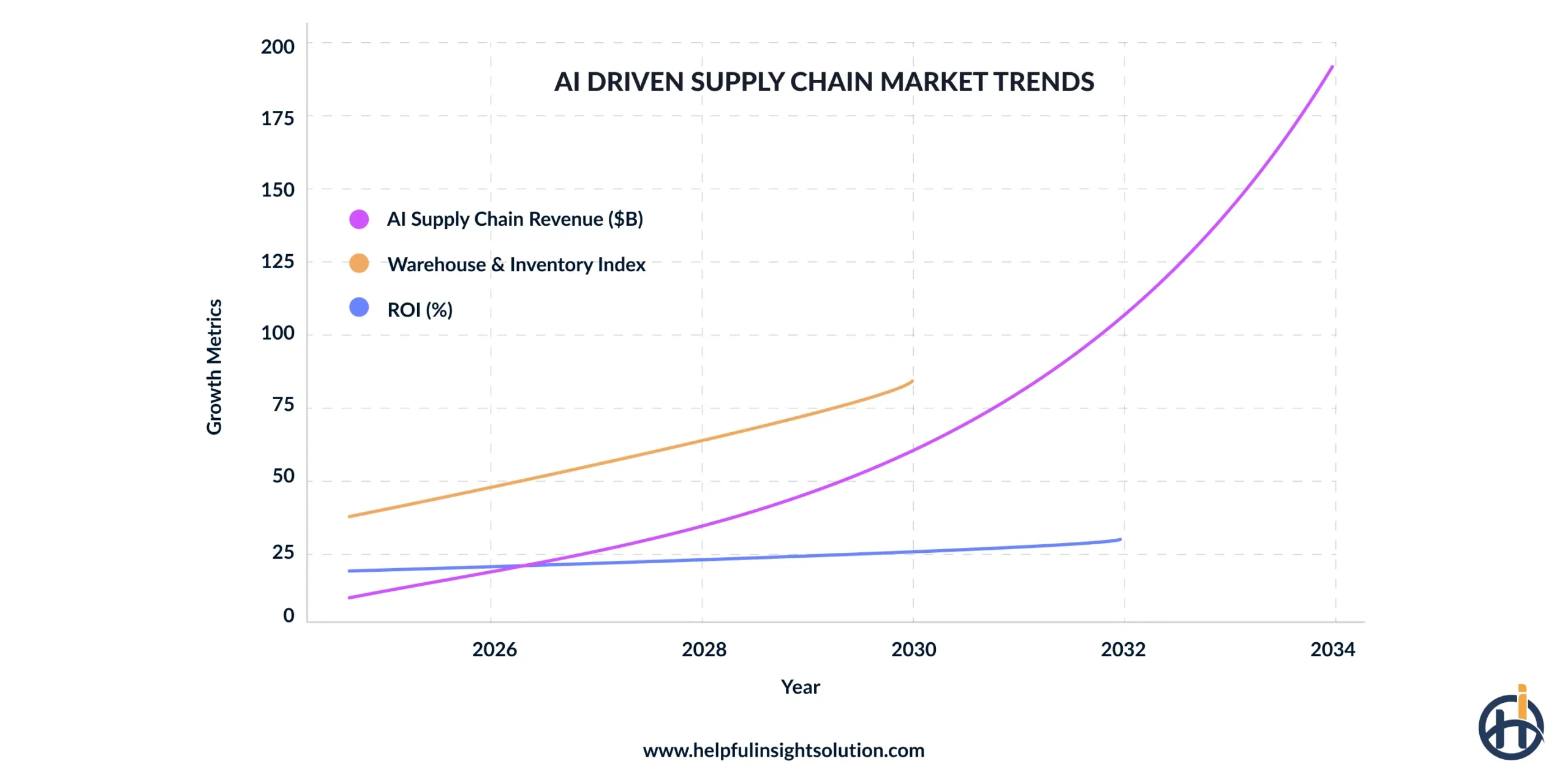

Current Scenario of the AI Supply Chain Market

Since the introduction of AI for supply chain management, the market has expanded rapidly, impacting business investors across the globe. The stats below represent the potential of the industry to grow further in the future with more investments and innovations:

- Last year, the revenue generated by the AI supply chain market was $9.9 billion, which will grow to $192.5 billion by the end of 2034.

- The industry is growing at a rate of 39% CAGR between 2025 and 2034. This is because the USA is dominating at a similar rate of 39.2% in this tenure.

- The automotive segment has the largest share of 17.7%, followed by the food industry and the manufacturing sector.

- The warehouse and inventory management applications have a 32.8% market share and are growing at a rate of 20.6% CAGR till 2030.

- The current ROI for supply chain businesses is 20%, which will rise to more than 30% by the end of 2032.

The Gen AI market in supply chain has created multiple opportunities for entrepreneurs in 2026 and beyond. It’s time to choose the best AI business ideas that will help to manage logistics tasks and handle inventory operations easily.

How Does AI Boost Supply Chain Management?

You must know the role of AI in supply chain management before integrating it with logistics software. Here, we will study the key AI roles in the supply chain industry:

1. Strategy for AI Analytics

The future of AI in the supply chain industry is advanced analytics and prediction-based demand forecasting. This strategy helps to build modern software to handle complex supply chain operations and streamline various logistics features for users.

2. AI Portfolios

The use of AI in portfolio management helps to build accurate business profiles, displaying their services and testimonials. This AI-driven supply chain role allows people to choose the best features to accomplish various inventory or logistics processes.

3. GenAI Co-Pilots

The role of Generative AI for supply chain management is to analyze delivery routes and networks before creating a model. The AI-enabled voice or chat assistants guide handlers and market vendors through different inventory and logistics operations.

What are the Benefits of AI-Enabled Supply Chain Systems?

Several benefits of AI in supply chain are available for entrepreneurs presently, allowing them to invest more. Let’s observe some major advantages of AI-driven logistics systems in this section:

1. Improved Forecasting Features

AI-enabled supply chain systems analyze historical data signals to deliver precise forecasting features. The Generative AI in supply chain maintains optimal inventory levels and avoids overproduction.

2. Operational Cost Reduction

AI-powered circular supply chains streamline production planning and resource allocation to reduce operational costs. It is possible through lower wastage, automated workflows, and better vendor selection.

3. Enhanced Logistics Visibility

Various top AI agents provide enhanced tracking and logistics visibility for various delivery networks. With AI-driven supply chain optimization, you can detect delays and improve customer communication.

4. Faster Decision-Making

With automated analytics, AI supports faster decision-making in complex logistics environments. It is among the best benefits of AI in the supply chain that enables businesses to respond to market changes.

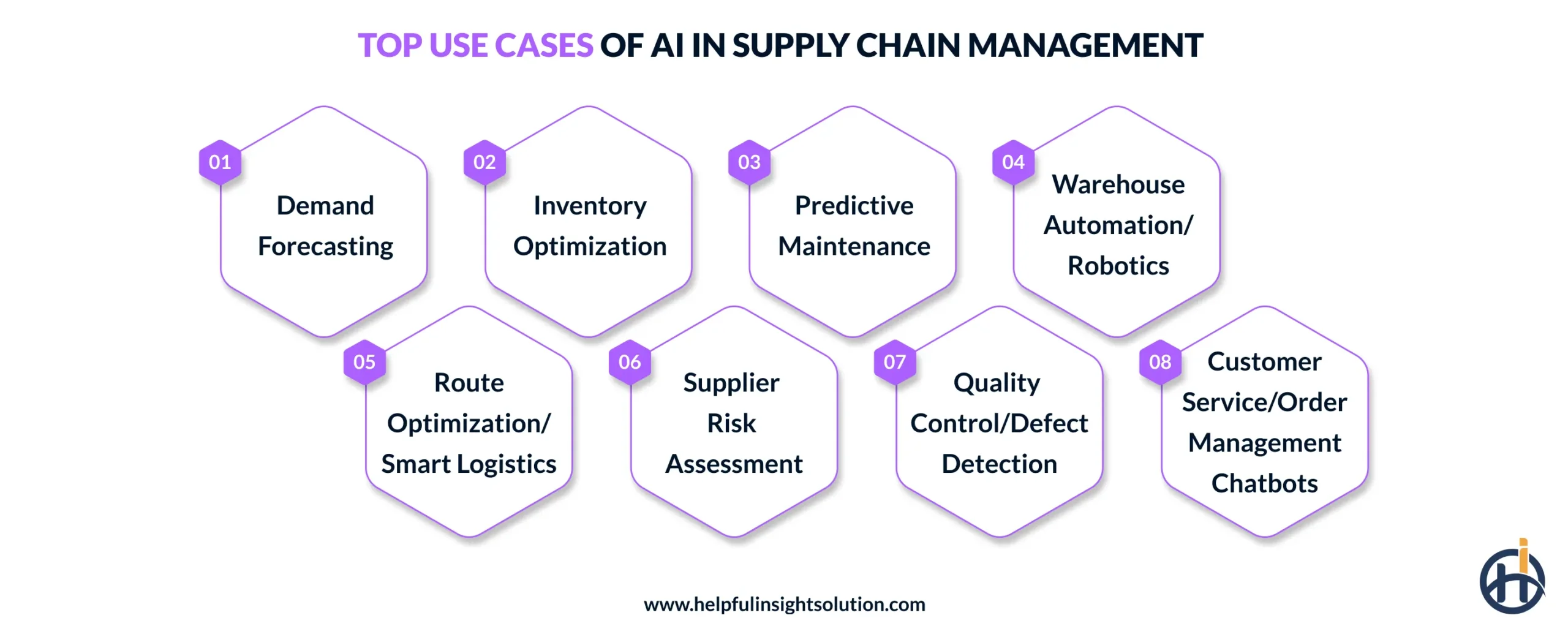

Top Use Cases of AI in Supply Chain Management

Business investors can target various AI in supply chain use cases to improve inventory tasks. In this section, we will understand the best AI application in the logistics industry for 2026 and beyond:

1. Demand Forecasting

AI-powered demand forecasting analyzes sales history, business promotions, and external signals. It is among the top Generative AI use cases in supply chain that target market trends. Machine learning models continuously learn from real-time data to predict future product needs with high accuracy.

This helps businesses reduce bullwhip effects and align production schedules with actual consumption patterns. As a result, companies improve revenue planning while minimizing waste and stockouts.

2. Inventory Optimization

It is beneficial to implement AI for Business Process Automation optimize inventory operations. It is one of the best use cases of AI in supply chain that helps to determine the right stock levels. The system evaluates lead times, service-level goals, and storage costs to balance supply with fluctuating demand.

Automated recommendations guide replenishment and prevent over-ordering or excess capital blockage. Various organizations gain better working efficiency and smoother business cycles.

3. Predictive Maintenance

Artificial intelligence enables predictive maintenance by monitoring sensors embedded in machines, vehicles, and equipment. These AI applications in the supply chain use advanced analytics to detect anomalies. Additionally, it estimates failure probabilities before system failure.

Maintenance teams receive alerts to schedule repairs with cost-effective time and strategy. This approach extends asset life and avoids unplanned disruptions in the supply chain management.

4. Warehouse Automation/Robotics

AI-driven warehouse automation coordinates smart robots for picking, packing, and sorting. These supply chain automation use cases allow regular movement of products. Computer vision systems track goods and optimize space utilization inside fulfillment centers.

The technology accelerates order processing while reducing human errors and labor dependency. Additionally, it allows warehouses to become highly productive, safe, and scalable for businesses.

5. Route Optimization/Smart Logistics

Smart logistics platforms use automated services for supply chain management and tracking. It can calculate optimal delivery routes by considering traffic, fuel cost, and delivery priority. These models dynamically adjust delivery plans when conditions change instantly.

It enables fleet operators to achieve faster deliveries with lower carbon emissions. This improves the overall customer experience through reliable and transparent shipment tracking.

6. Supplier Risk Assessment

AI-based supplier risk assessment evaluates financial health, geopolitical exposure, and compliance history. Various AI solutions in supply chain are regulated based on their delivery performances. Natural language processing scans news and contracts to identify hidden security threats.

The technology allots different procurement teams to diversify sourcing and negotiate better delivery terms. This can strengthen resilience capability against supplier failures and errors.

7. Quality Control/Defect Detection

Among the top use cases of Generative AI, this model improves quality control through vision analytics. It regularly inspects raw materials and finished products based on specific production lines. This system easily identifies microdefects that are invisible to the human eye.

These supply chain AI use cases provide automated rejection and feedback loops to enhance production standards. They allow valuable brands to protect their reputation and reduce return rates instantly.

8. Customer Service/Order Management Chatbots

AI-powered chatbots assist in order management by answering instant shipment queries. It is one of the best AI applications in supply chain management that helps in processing routine service requests. They can integrate with ERP systems to provide regular status updates and documentation.

These virtual agents operate 24/7 with multilingual support, handling millions of user queries. Business investors should reduce service costs while increasing the overall customer satisfaction.

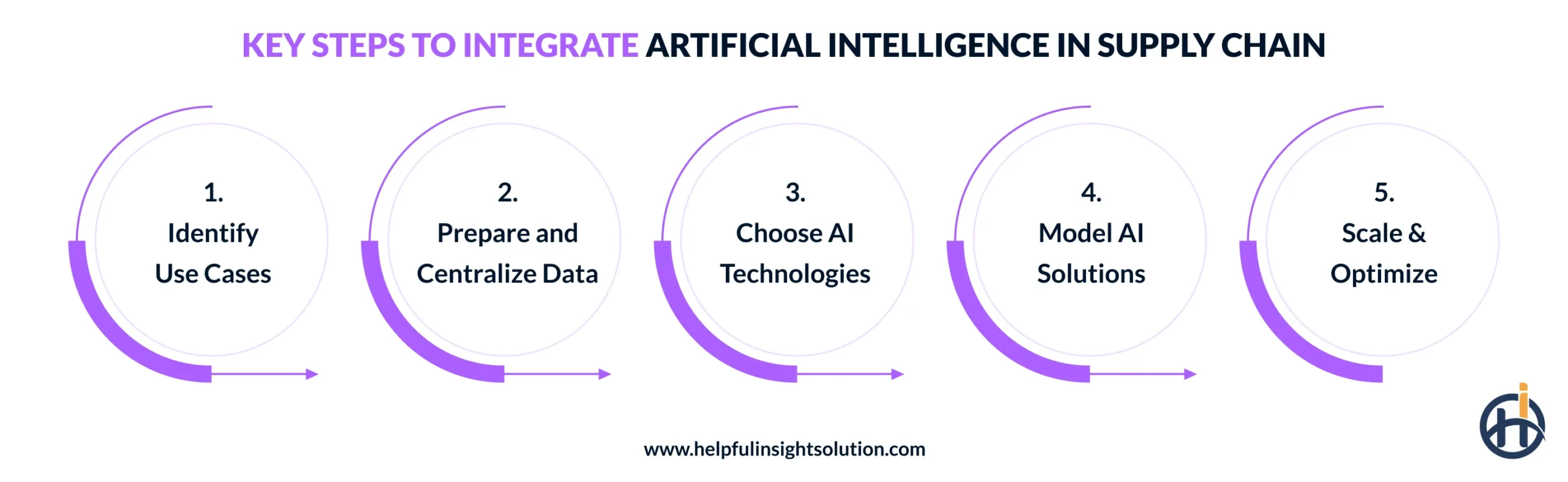

Key Steps to Integrate Artificial Intelligence in Supply Chain

Do you know how to implement AI in supply chain? If not, then this section is for you. A generally used process is discussed with detailed information in this section, with targeted stages:

1. Identify Use Cases

To know how to implement AI solutions in supply chain, start by mapping user-centric pain points such as demand forecasting, inventory imbalance, or logistics delays.

You must engage stakeholders from procurement, warehousing, and planning to prioritize high-impact scenarios. It is important to define clear business outcomes and KPIs to measure the value of AI.

2. Prepare and Centralize Data

You should collect data from ERP, WMS, TMS, and partner systems into a unified or easily accessible platform. Using AI for supply chain planning helps to clean and standardize records to remove duplicates and ensure consistent data formats.

It is necessary to establish basic governance rules so that trusted data becomes the foundation for AI decisions.

3. Choose AI Technologies

For developing AI-powered supply chain solutions, you must select technologies like machine learning, predictive analytics, or Gen AI based on the chosen use cases. It is crucial to evaluate vendors and tools for integration capability with existing supply chain software.

You must consider AI for enterprise security and efficiency with the total cost of ownership before finalizing.

4. Model AI Solutions

Business investors can develop and train AI models using historical supply chain data with advanced analytics services. They must test the logistics solution through different pilots to validate the accuracy and functionality of the software.

You should refine the supply chain workflow with generative AI so that human teams and AI collaborate effectively.

5. Scale & Optimize

It’s time to deploy successful AI solutions across multiple regions, suppliers, distribution centers, and operating systems. Entrepreneurs should monitor performance continuously and retrain models as per the market conditions.

Use AI for supply chain optimization from adoption to automation to improve the overall logistics ecosystem.

What are the Challenges with AI for Supply Chain Management?

There are multiple challenges that businesses face with AI for supply chain management and logistics. It is crucial to know these risks before investing money in the development of AI-enabled systems:

-

Data Quality Issues

As AI is a complex technology, it may affect the quality of the data, which leads to model inaccuracy. It may modify the user information and deviate from the trends based on the given instructions.

Solution: Build enhanced AI supply chain solutions that support data quality and authenticity.

-

High Implementation Costs

The AI agent development cost is high because various market factors influence AI models and algorithms. This directly affects the final results by increasing the service rates for users.

Solution: Use third-party technologies with AI in the supply chain industry to reduce expenses.

-

Change Management & Skill Gaps

Another challenge with artificial intelligence in supply chain management is handling irregular skill changes. People feel difficulty in adapting to the AI technology, which creates a social gap.

Solution: Implement advanced logistics guides and inventory tutorials to help users instantly.

Final Thought!!

Entrepreneurs are building the top supply chain AI solutions to empower their business and satisfy user preferences. It is the right time for you to start with artificial intelligence to enhance logistics operations, manage inventories, and mitigate risks.

In 2026, you should approach a reliable AI development services provider who has experience with advanced AI tools and knows how to integrate them into existing systems. Additionally, it must provide skilled professionals who are reliable and dedicated.

As the use of AI in supply chain has increased over the past few years, businesses are now focused on the implications of this technology. The response and impact of Generative AI in supply chain is positive, allowing more investment and time.

This will help you to resolve technical irregularities, target more customers, and increase the overall brand value for future growth.

FAQs

In supply chain management, AI analytics tools are used to study various business and user data. A few major roles of AI analysis in logistics are as follows:

- AI analytics predicts demand through historical data and market trends.

- It optimizes inventory and warehouse operations by automating decisions.

- AI detects disruptions, assesses risks, and improves supply chain visibility.

A supply chain business has multiple operations, such as inventory and risk management. The implementation of artificial intelligence helps to enhance delivery patterns, optimize routes, track stock availability, and improve warehouse efficiency. Additionally, AI helps in managing the product identity with advanced quality checks.

Artificial intelligence in supply chain management is used to secure various operations and logistics systems. AI uses the following measures for the safety and privacy of information:

- It uses prediction to detect backdoors and system loopholes.

- Perform advanced analytics to monitor the progress of security algorithms.

- Automation identifies suitable solutions that can be superimposed easily.

The average cost of building simple logistics software is between $8,000 and $25,000 because of limited technologies. The overall development cost increases to $30,000 or more due to the integration of smart AI analytics features and complex algorithms. There are multiple factors, like the location and experience of developers, that affect the total price.

To create advanced supply chain management software, businesses should know the hiring process of AI developers. Key steps of hiring are discussed in the following manner:

- Build a plan listing business requirements and platform needs.

- Analyze previous work and study verified client testimonials.

- Conduct interviews to judge technical knowledge in AI.

- Ensure ethical skills before signing a non-disclosure agreement.

- Finalize candidates and discuss AI-driven outcomes of the platform.